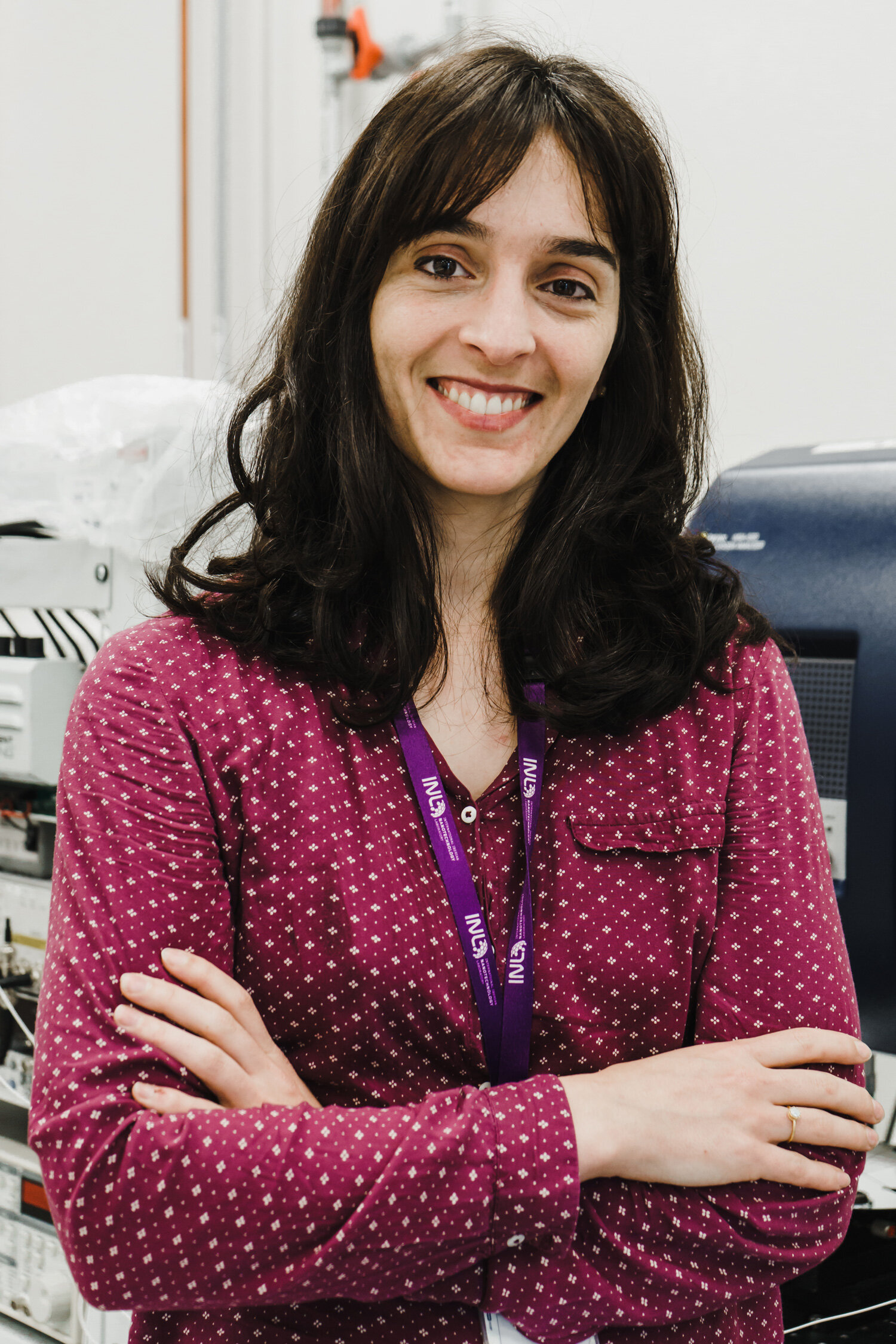

Celebrating WOMEN IN SCIENCE: Interview with Rosana Dias

February 10, 2020

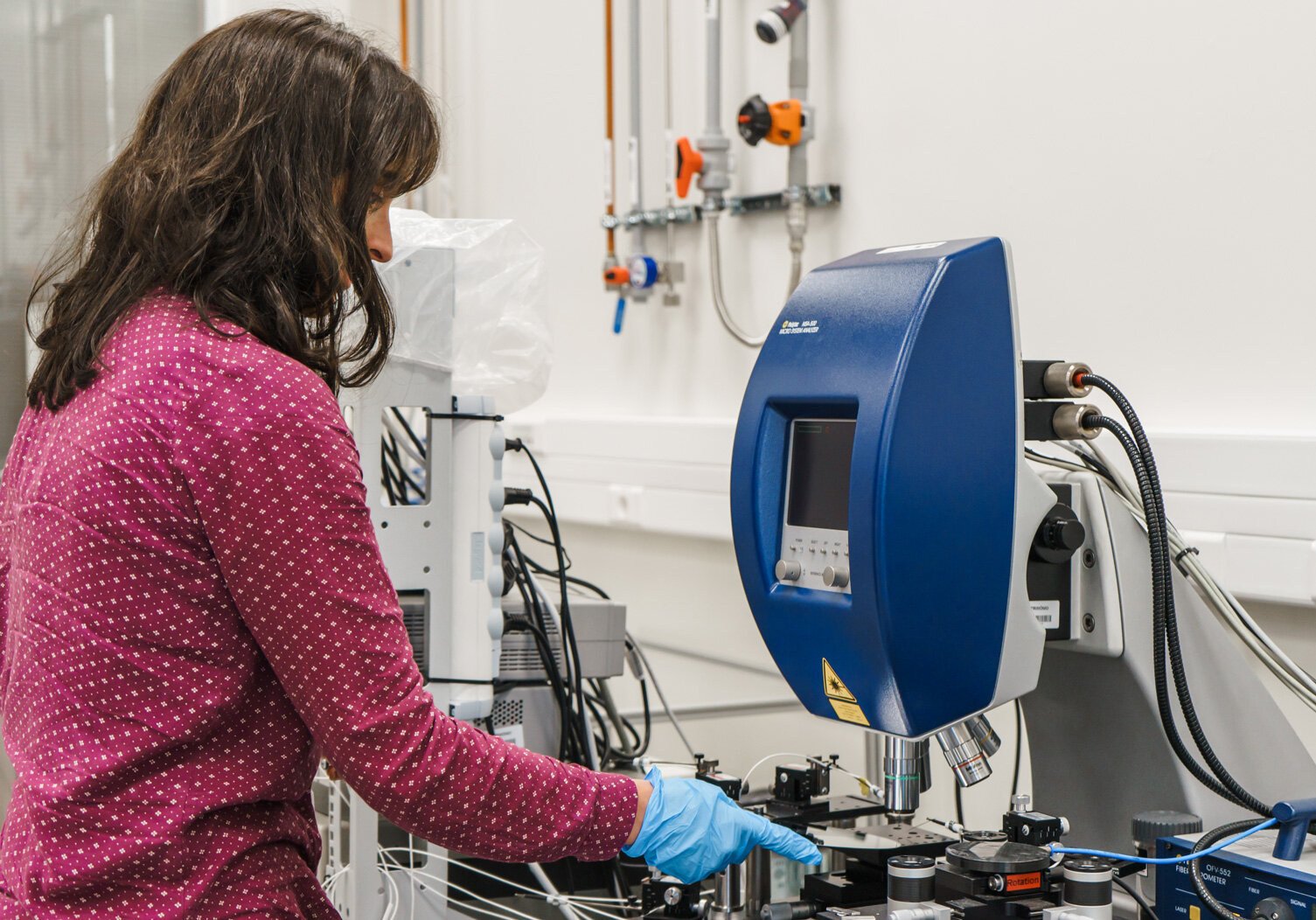

Rosana Dias is a Staff Researcher in the Micro and Nanofabrication Department (Microfabrication and Exploratory Nanotechnology research group) at INL. Her expertise concerns the development of sensors and actuators to meet the technical challenges faced by society and industry. She has large experience in modeling, design, fabrication, and testing of MEMS devices. Her research interests range from mechanical sensors (eg. acceleration and magnetic field sensing) to energy harvesting devices (piezoelectric AlN and EMF-based induction) and flexible substrate-based applications.

Can you tell us a bit about your career path and how did you come to INL?

I visited INL as a PhD student in the MEMS field Microelectromechanical systems (my supervisor was Luis Rocha, which had recently become an associate at INL). During that time I started working in the cleanroom with João Gaspar. After finishing my PhD, in 2012, and after working on a post-doc at the University I got a Marie Curie Fellowship on the NanoTRAINforGrowth program. During the two-year fellowship, I acquired different competencies in several fields and further expanded my experience in microfabrication, which allowed me to pursue a research staff position.

What is the importance of your research?

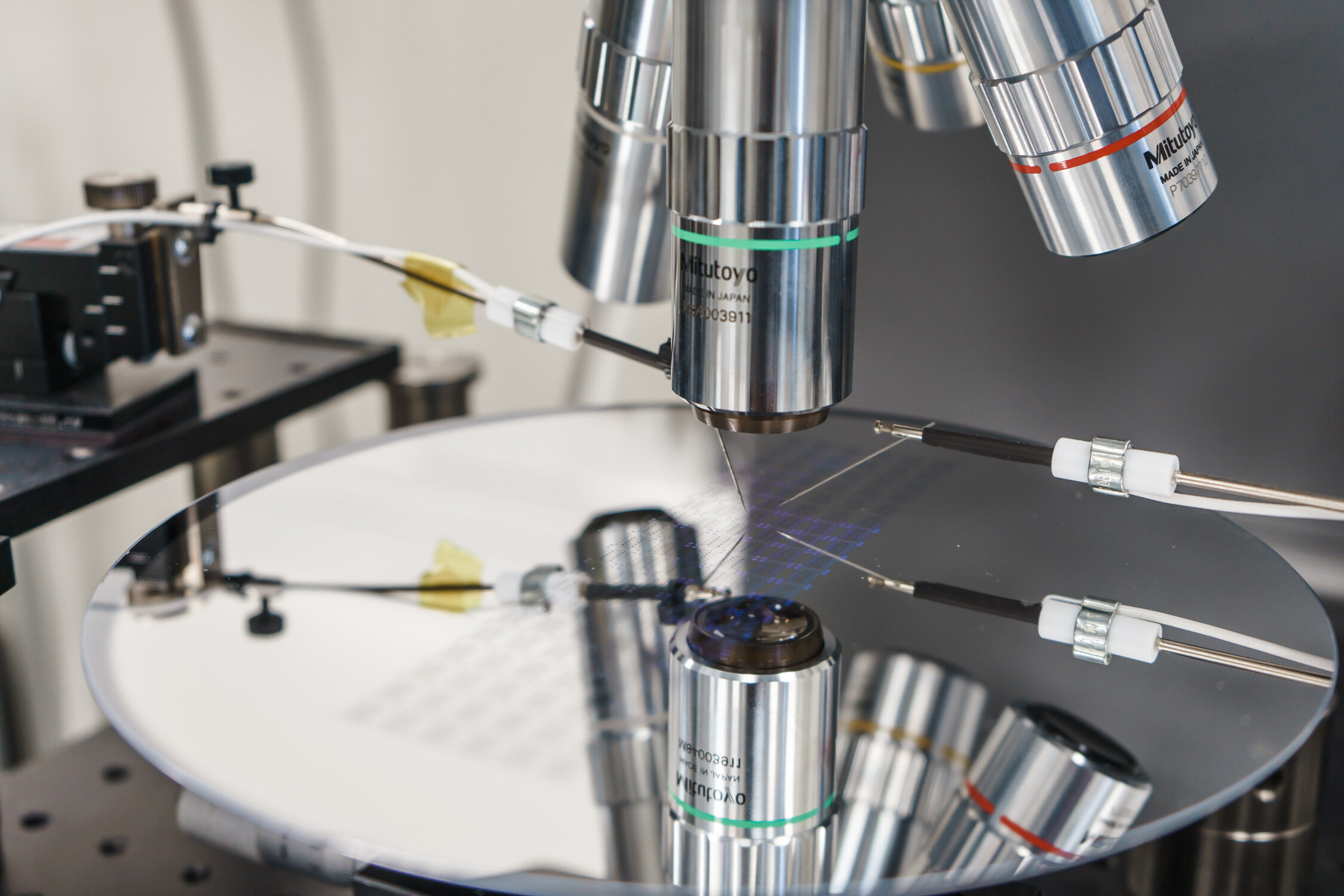

The development of MEMS sensors means the creation of new fields of application that were previously impossible with macroscale sensors, but also the miniaturization of existing sensors allows the spread of technology into our life. I mean, IoT, big data, it all relies on ubiquitous sensor systems, that in turn requires sensors with small form factors, low power consumption and low cost, without any loss in performance.

What is the most exciting discovery you made during your research?

I’m proud of working on the development of novel physical sensors, using uncommon transduction principles, such as the pull-in time accelerometer.

Finding new microfabrication methods to address a technological obstacle or limitation is also very exciting such as using process imperfections to fabricate nanostructures.

Briefly, what excites you about your work?

Miniaturization of macroscale sensors with exquisite performance is a challenge because it requires a change in paradigm and looking at an existing problem or challenge from a different perspective, and also finding creative ways to address it. And that is a fun process.